Project 14: Create a 4 x 6 foot Karaoke Stage.

2019-02-02

Objective:

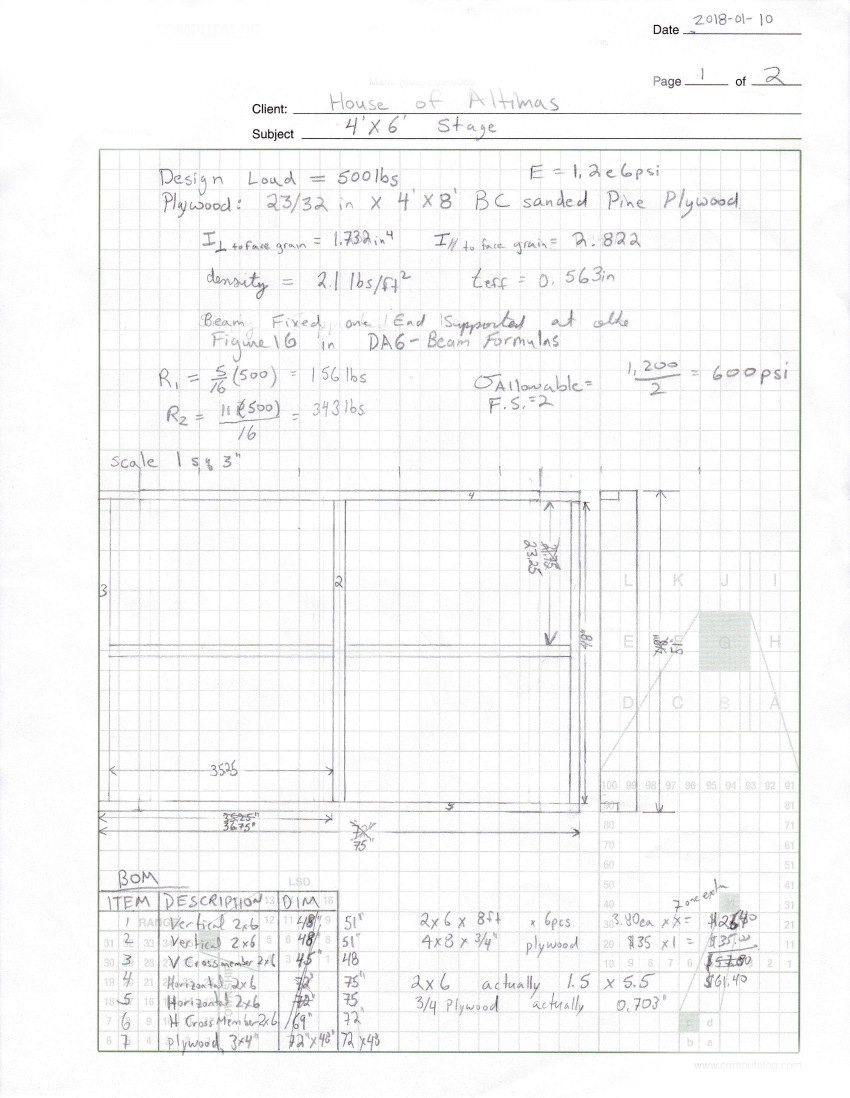

To build a 4' x 6' stage for amatuer karaoke night. Ltimas.com Productions was retained to design, protoytpe and produce a stage for a house party. Objective of the stage is to provide a designated space for the karaoke singing. This is intended to allow the participants to take the performance to the next level.

The architecture of the stage is manufactured wood. The stage is only a modest 6.25" lift and has a painted plywood surface.

Structure Detail and Overall Dimensions:

72 in. Long

48 in. Wide

6.25 in. High

125 lbs Mass

Capacity 500 lbs

Materials:

1. 6x 2" X 6" X 8" SYP Lumber. Cost $3.98 ea.

2. 3/4" X 30" X 48" Plywood. Cost $35 ea. 3. 16x 1/4-20 UNC E-Z Lok Inserts $8.00 all. 4. 16x 1/4-20 UNC X 2.0 in. long bolts. Cost 3.50 all. 5. 16x 1/4 Washers. Cost $1.00 all. 6. 14x #10 2" Wood Screws. Cost $0.80 all. 7. Oil Based Primer. Cost $10.00. 8. Oil Based Paint. Cost $10.00. 9. Polyurethane floor paint. Cost $15.00. 10. Plastic wood. Cost $7.50ea. 11. 9" Roll, 3 pack, Wstr Pro 9" X 3/8" nap. Cost $11 all. 12. 2x 9" Paint trays. Cost $3. 13. Tack Clothes. Cost $5 all. 14. 10x Orbital sanding pads. Cost $3.50 Total cost of all materials used included consumables $140 USD.Tools:

1. Makita 7 1/4 Circular Saw, est. cost $100 2. Makita 4 1/2 Angle Grinder, est. cost $69 3. Makita Orbiting Sander 5.0" VSP, est. cost $79 4. Ryobi Jig Saw, est. cost $69 5. 3/8 Drill, corded, est. cost $50 6. Black Oxide Drill bit Set (29-Piece). est. cost $27 7. 6-Pc. Spade Bit Set, est. cost $10 8. 2x 4in C-Clamps., est. cost $12 ea. 9. 2x 8in C-Clamps., est. cost $15 ea. 10. Ratchet Wrench 3/8, est. cost $13 11. 7/16 socket, est. cost $2 12. 7/16 wrench, est. cost $3 13. Aluminum Speed Square, est. cost $8 14. 25' Tape Measure, est. cost $10 15. 18" Stiff Ruler, est. cost $8 16. Screw Driver Interchangeable Set, est. cost $7 17. Screw Driver 3/8 X 8", est. cost $8 18. 9" polycast torpedo level, est. cost $3 19. 48" Johnson structo-cast level, est. cost $ 9.98 20. Wood Chisel, est. cost $5 21. 8 in. Long Nose Pliers, est. cost $ 5.17 22. 4.5" X 0.045" Cut Wheel, $2.75 23. 4.5" X 0.25" Grind Wheel, $4 24. Purdy 2.5" White Bristle 100% Natural, soft, est. cost 14.47 25. 9" Roller Frame. Cost $4 ea. 26. 2" Putty Knife, est. cost $7.97 27. Safety Knife, est. cost $6.98 28. Paint Spinner, $9 29. EZ-Lok, Drive Tool, 500-3, est. cost $9.50 30. Work Bench, refer to project 8. Cost of material $115. Total cost of all tools if all bought new for project is approximately $715 USD.Design:

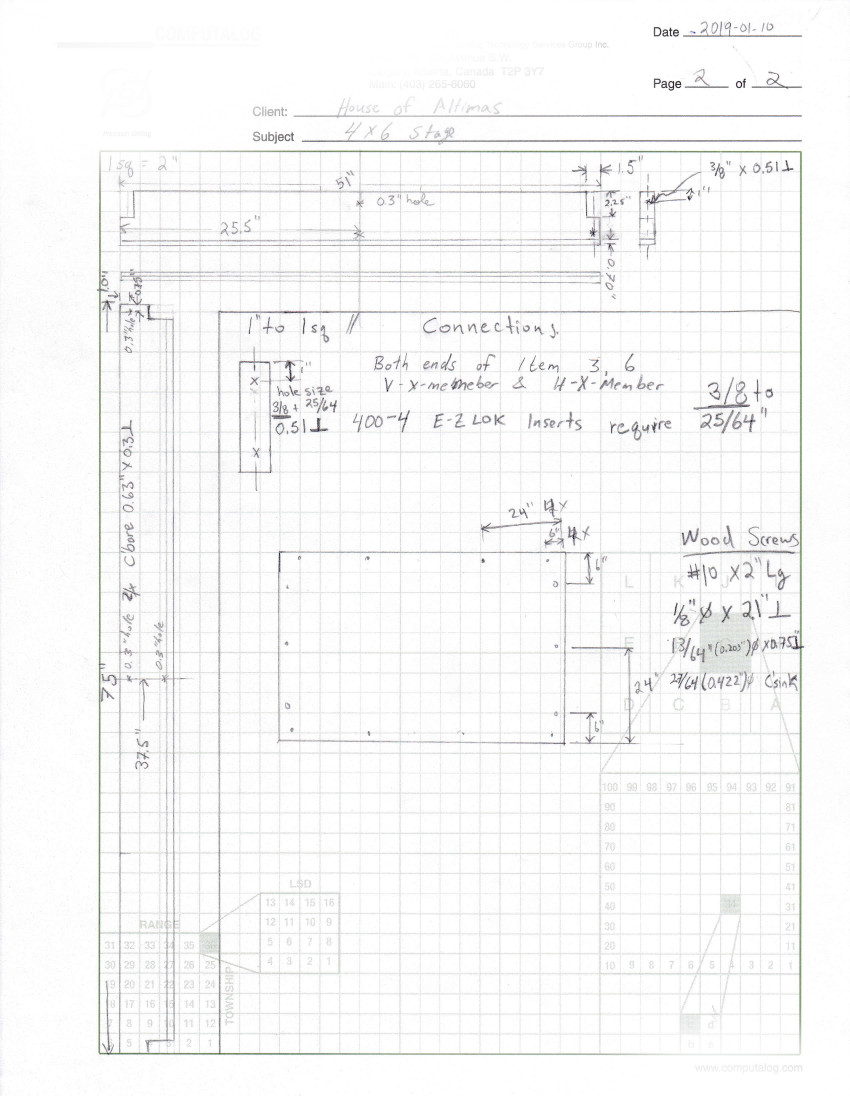

Note 1: Original plan was to use 1/4 threaded rod and nuts, however, it was too difficult to install the ends and fit the nuts when joining the ends. The cost for the threaded rod and nuts was only modest lower in cost.

Note 2: The joining of the 45 in. v-cross member to the 69 h-cross member are using ¼ bolts and washers, and E-Z Lok inserts spaced 3.5 in. apart.

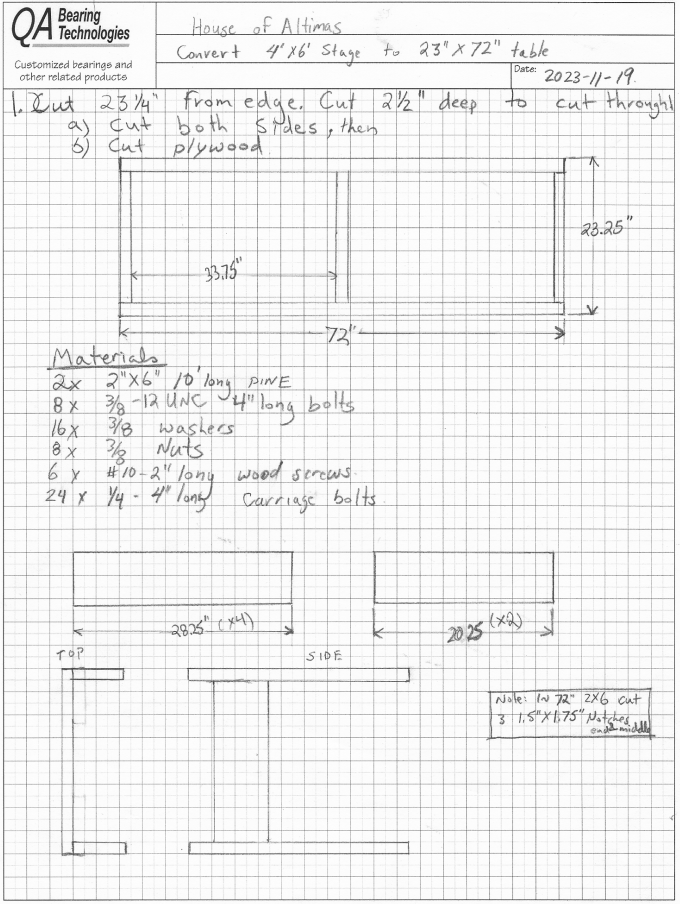

Note 3: There are some geometry errors in the geometry of scans, you must complete as necessary.

Note 4: The plywood is attached using #10 X 2.0 in. wood screws, spaced 20" apart. The platform must be easily removable so designed for minimum anchoring screws.

Note 5: The original intent of the design was to be able to disassemble. However, it became obvious for cosmetic reasons that the joints had to be filled and painted making disassembly impractical. If designing again would consider other joining methods besides mechanical fasteners.

Note 6: The polyurethane floor coating was durable but did shown dents after heavy use during karaoke night. An epoxy based coating may have had better durability.

Procedure

1. Cut all 2X 6 lumber to length:

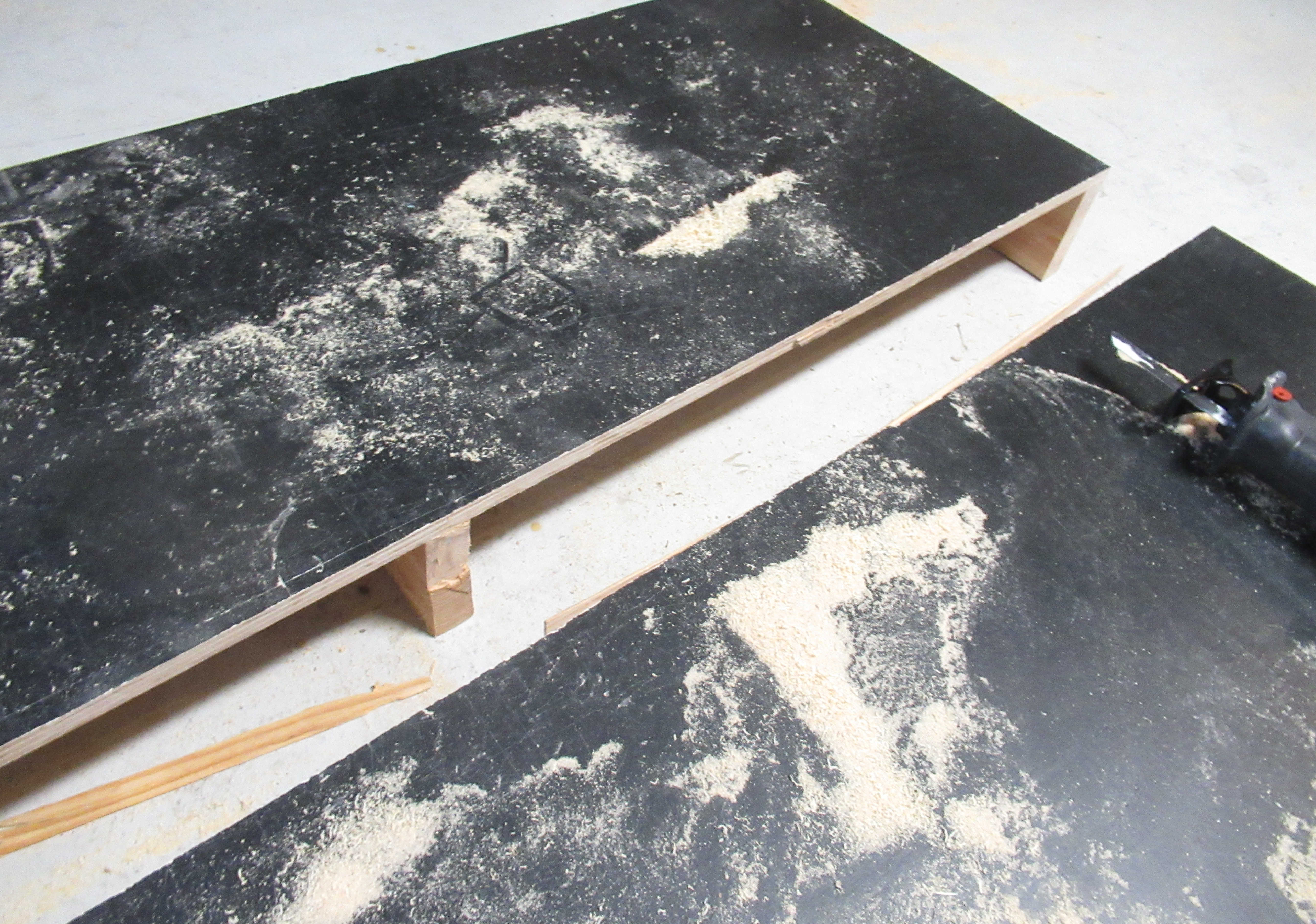

2. Cut plywood:

3. Cut notches into ends of the 4 pieces of 2X6 along perimeter. Do this set using a jig saw. Smooth out with oribtal sander.

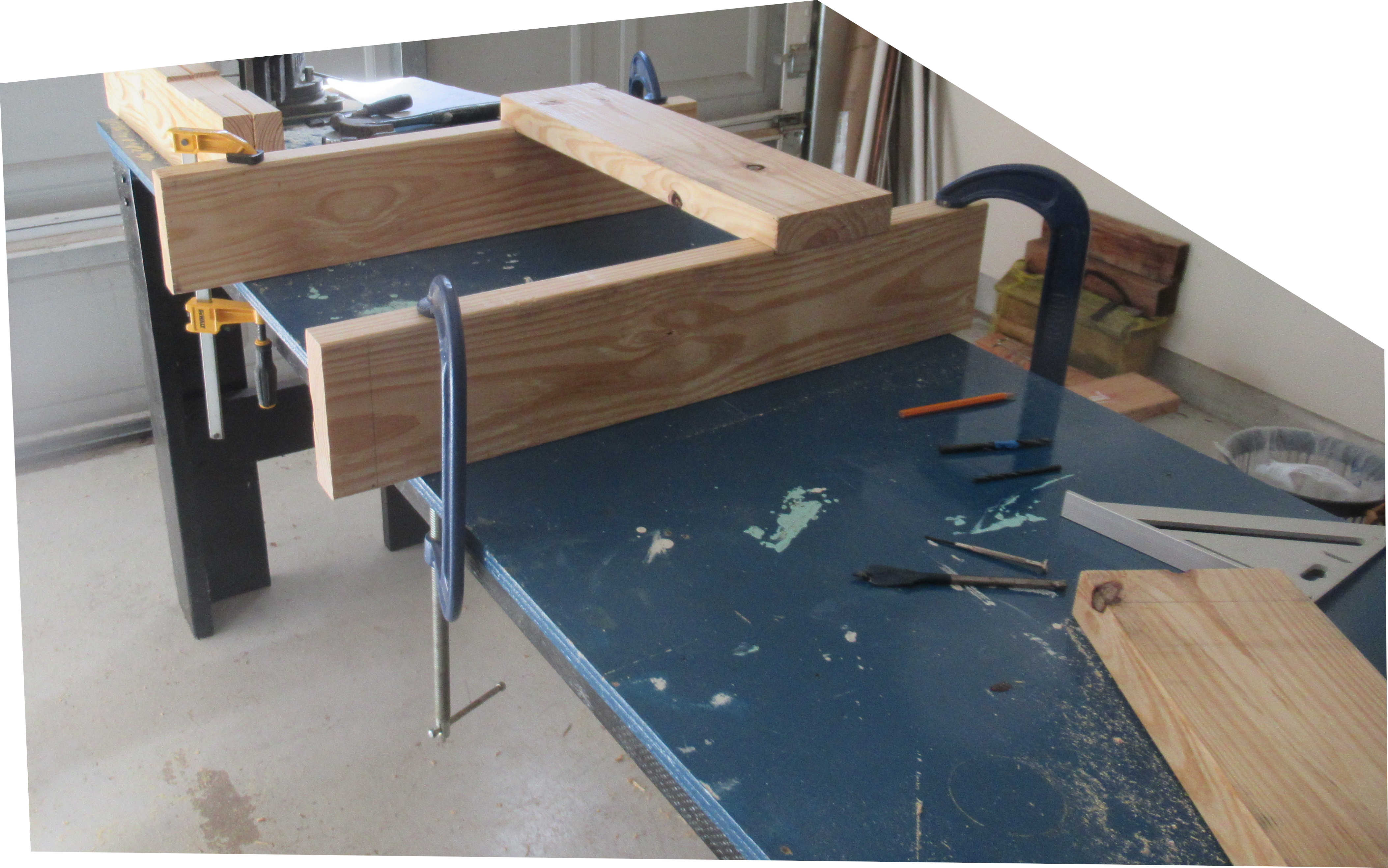

8. Drill two holes 3/8" hole, 0.5" depth, spaced 3.5" apart in the ends of each cross member. Then install E-Z Lok inserts.

9. Drill two 0.30" holes, 3.5" apart centered in each frame support.

10. Fit the cross members in the frame and install 1/4 bolts and washers.

12. Drill pilot holes 1/8" X 2.1" deep, body hole 13/64" X 0.75 deep, 27/64" c'sink. Then screw top to frame.

13. Fill in all connections, let dry and sand. Repeat until smooth.

14. Prime and paint with flat black paint.

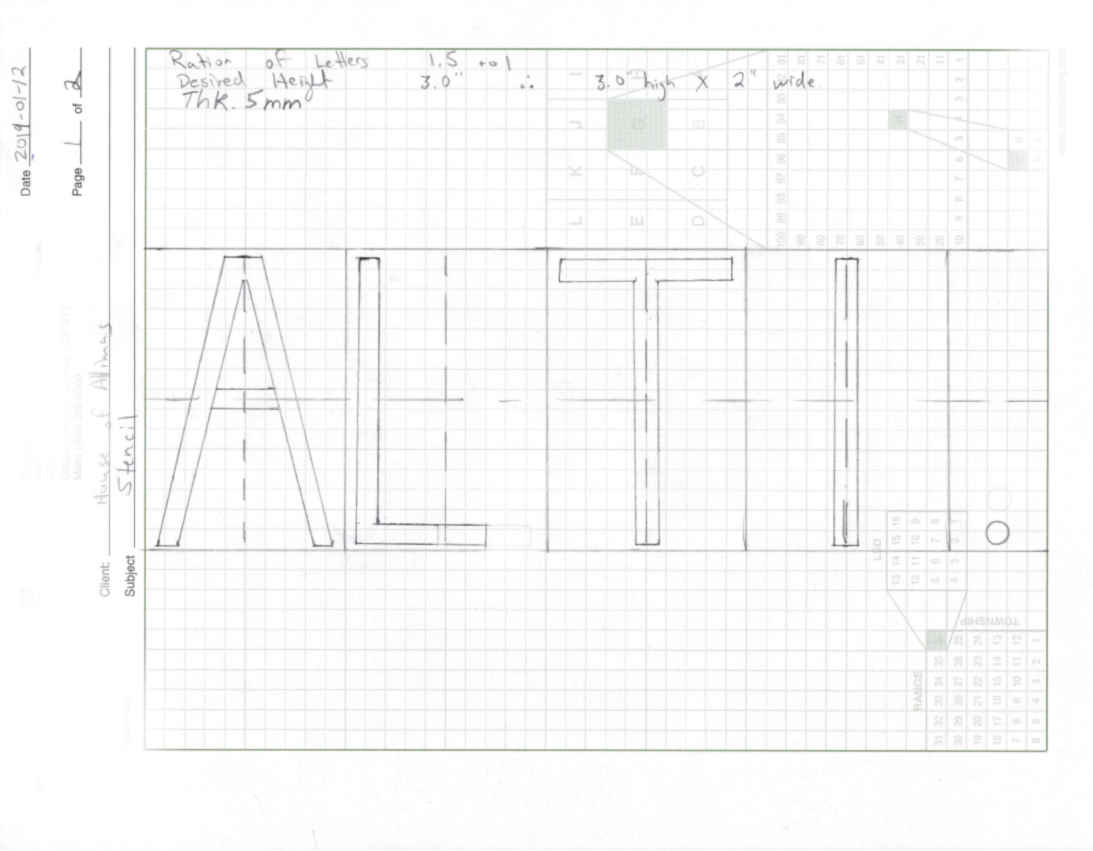

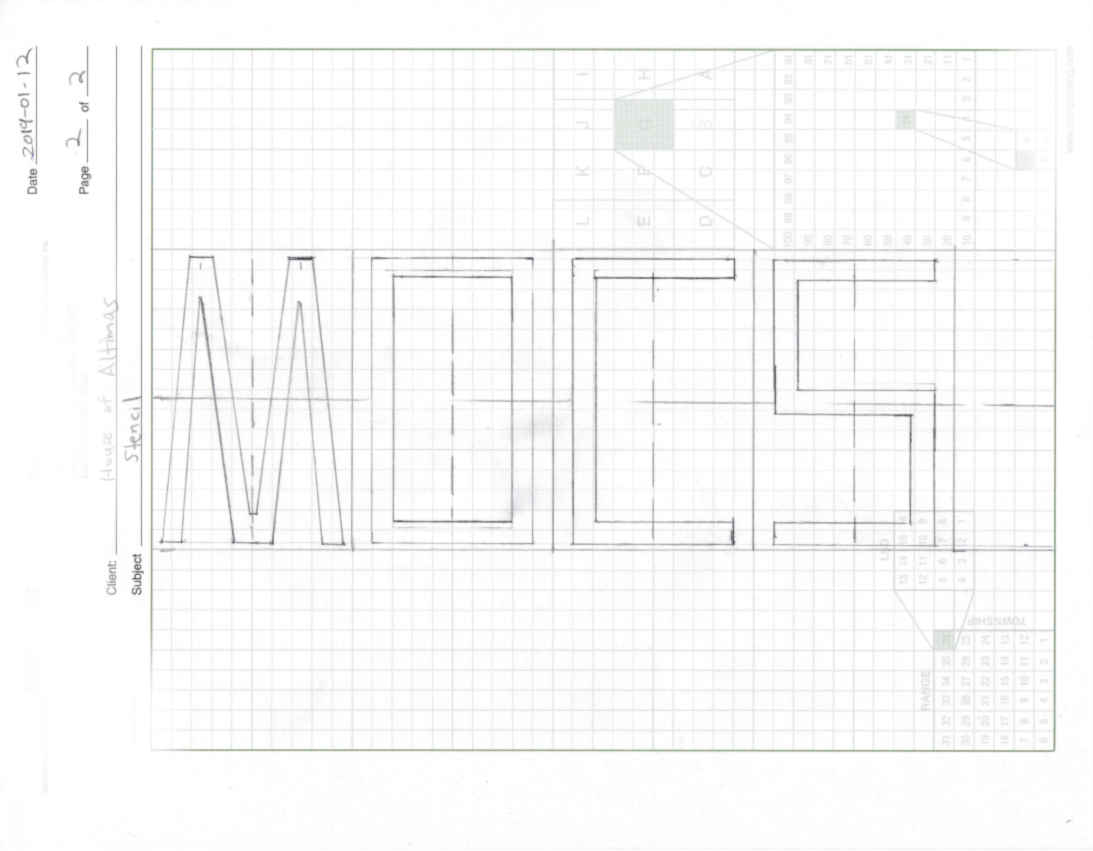

15. Apply stenciling, recommend using rollers. I used spray and white overspray gave a bad look. Stencil was painted over for the first unit.

16. Coat with polyurethane, sand with 150 grit and reapply. Repeat at least 3 times.

17. Time to rip up the stage. 18. Tired of Karaoke? Why not turn the stage into a table. 2023-11-26 Objective:

To convert a 4' x 6' karaoke stage into 2 stout tables. Table 1 72 in. Long 25 in. Wide 29 in. High 82 lbs Mass Capacity 500 lbs Other table will be similar but 23 inches wide Materials: Below is materials required per table Copyright © 2023 by Gregory Altimas

6. Lay out frame as in step 3. Thread in the 1/4 bolts with washer and lightly torque. Repeat torque to make sure it is tight and no inserts stripped out.

7. Cut the cross lap joints in the cross members.